The offshore energy sector has entered a defining decade of low-carbon transformation. After the success of Floating Liquefied Natural Gas (FLNG) — which unlocked stranded offshore gas reserves — engineers are now turning toward Floating Carbon Capture (F-CCS), a technology designed not to produce energy but to clean it.

According to the International Energy Agency (IEA), the offshore sector contributes nearly 7% of global CO₂ emissions, much of it from FPSOs and gas compression units. Floating Carbon Capture (F-CCS) directly addresses this challenge by converting existing offshore assets into carbon-neutral platforms.

F-CCS allows offshore operators to capture, compress, and store carbon dioxide (CO₂) directly at sea, converting emissions from platforms and FPSOs into opportunities for decarbonisation.

Just as FLNG projects like Coral South, Petronas PFLNG Dua, and Shell Prelude FLNG redefined offshore gas production, F-CCS represents the next logical step — transforming emission-heavy assets into climate-positive infrastructure.

What Is Floating Carbon Capture (F-CCS)?

Floating Carbon Capture (F-CCS) is an offshore system that captures CO₂ from production facilities, FPSOs, or FLNGs, compresses it, and either stores it in depleted reservoirs or ships it to onshore storage hubs.

Think of it as the mirror image of FLNG: instead of bringing gas up to the surface and liquefying it, F-CCS captures exhaust gases and sends them back underground in liquid form.

According to the Global CCS Institute 2024 Report, over 200 carbon-capture projects are under development worldwide — many evaluating floating or modular configurations suitable for offshore use.

The concept evolved naturally from FLNG and FPSO innovations, where operators learned to handle complex process modules on moving vessels. F-CCS applies the same marine engineering principles—topsides integration, motion control, and modular skids—but repurposes them for emission mitigation instead of production.

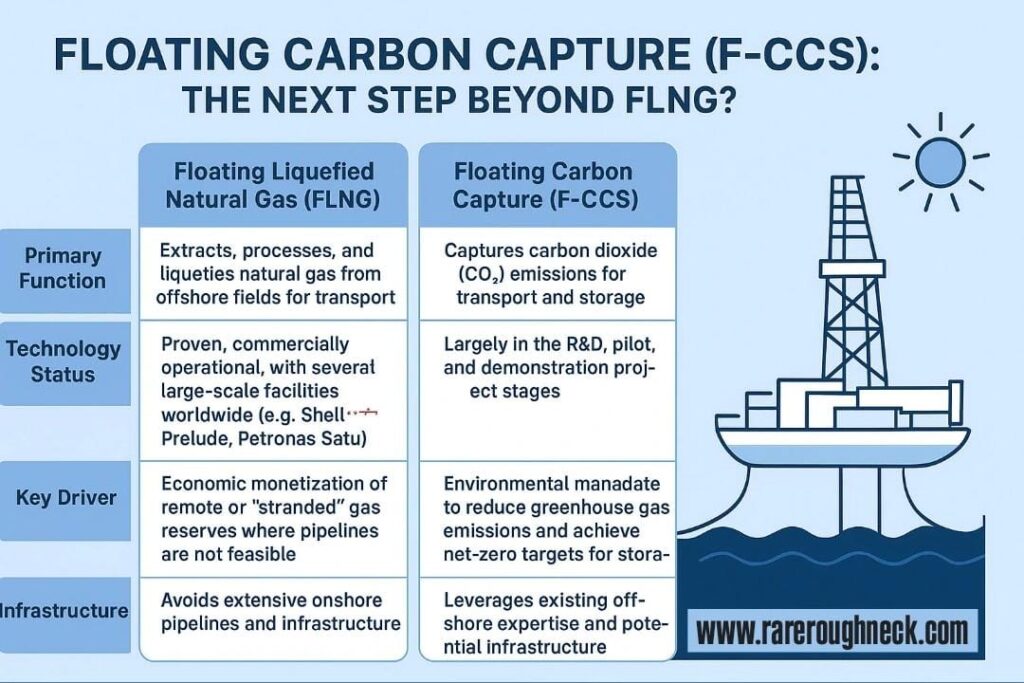

F-CCS vs FLNG — A Comparative Overview

| Feature | FLNG (Floating LNG) | F-CCS (Floating Carbon Capture) |

| Primary Function | Liquefies and exports offshore natural gas. | Captures and stores CO₂ emissions offshore. |

| Technology Maturity | Proven (Shell Prelude, Petronas PFLNG Satu). | Emerging, in pilot stages. |

| Key Driver | Monetisation of stranded gas. | Reduction of greenhouse gas emissions. |

| Infrastructure Needs | Minimal onshore footprint. | Uses existing offshore reservoirs for CO₂ storage. |

| Core Benefit | Expands offshore gas production. | Enables offshore carbon reduction and storage. |

| Challenges | High CAPEX, weather risks. | Energy consumption and regulatory uncertainty. |

To understand the FLNG legacy that inspired F-CCS, explore our detailed coverage of Floating LNG 2025

How Floating Carbon Capture Works

F-CCS units combine proven offshore process modules with carbon-capture chemistry. The sequence typically includes:

- Capture: CO₂ is separated from process or flue gas streams using amine-based absorption, membranes, or cryogenic separation.

- Compression: The gas is compressed to >100 bar to form a dense phase suitable for storage or transport.

- Cooling & Dehydration: Moisture is removed to prevent corrosion.

- Transport: Compressed CO₂ is transferred via pipelines or special LCO₂ shuttle tankers.

- Storage: Injected into depleted reservoirs or saline aquifers beneath the seabed.

- Monitoring: Real-time sensors track pressure and plume stability to ensure safe containment.

The modular design allows one floating unit to service several offshore fields — a practical advantage for operators managing multiple assets.

Engineering Design & Innovation

Modern F-CCS systems merge offshore engineering robustness with advanced capture technologies. Core modules include:

- Amine Absorber Systems: Chemical absorption remains the most mature approach for CO₂ capture offshore.

- Compression Trains: Multistage centrifugal compressors raise CO₂ to storage pressure (~110 bar).

- Dehydration Units: Molecular sieves or glycol dehydrators prevent hydrate formation.

- Cooling & Liquefaction Modules: Used when CO₂ is exported as liquid cargo.

- Digital Monitoring: Integrated with subsea controls for pressure and flow management.

Technip Energies, Petronas, and Hyundai E&C have each proposed hybrid FLNG–F-CCS designs, capable of either gas liquefaction or carbon capture depending on market demand — a concept particularly suited for Asia-Pacific decarbonisation targets.

Many of these design principles were first proven in FLNG projects like Petronas PFLNG Dua and Coral South FLNG, which paved the way for modular floating process systems.

Why Floating Carbon Capture Matters

- Decarbonises Offshore Assets: Captures CO₂ at the source — reducing Scope 1 and 2 emissions.

- Extends Asset Life: Repurposes aging FPSOs, rigs, and FLNGs into low-carbon facilities.

- Flexible Deployment: A single floating unit can service multiple fields.

- Supports Net-Zero Goals: Provides a tangible route for oil & gas producers to align with global climate targets.

- Creates New Supply-Chain Opportunities: For equipment manufacturers — CO₂ compressors, subsea valves, cryogenic pumps, and digital monitoring systems.

Global F-CCS Projects and Initiatives (2024-2025 Snapshot)

| Project | Location | Partners / Status | Key Details |

| Northern Lights Project | Norway | Equinor, Shell, TotalEnergies – Operational 2025 | First open-access CO₂ transport & storage hub in Europe. Includes LCO₂ shipping and offshore injection platforms. |

| Petronas–Technip Energies F-CCS Study | Malaysia | Conceptual design phase | Developing floating capture solutions for offshore gas fields; potential integration with PFLNG units. |

| MOL Offshore CCS Hub | Japan | MOL + JGC + Tokyo Gas | Plans for floating CO₂ storage & shipping hub to serve Asia-Pacific emitters. |

| Solvang Clipper Eris Shipboard CCS | Norway | Full-scale marine pilot | Tests post-combustion capture and offloading of LCO₂ at port. |

| SBM Offshore–Petrobras FPSO CO₂ Capture | Brazil | Feasibility Study 2024 | Evaluating retrofit modules for FPSO topsides. |

| Gulf of Mexico Studies | USA | DOE-funded universities | Assessing floating injection unit (FIU) concepts under carbon credit frameworks. |

These initiatives demonstrate that F-CCS is no longer a concept — it’s a pipeline of projects approaching commercial reality.

Technical & Economic Challenges

- High Energy Demand – CO₂ capture can consume 20–25 % of a platform’s output. Hybrid heat-integration schemes are being developed to recover waste energy.

- CAPEX & Scalability – A single 50 tonnes/hr module may cost US $100–150 million. Cost reduces with standardisation and series fabrication.

- Regulatory Uncertainty – Each jurisdiction (Norway, Malaysia, Japan) has different rules for offshore storage liability.

- Monitoring & Verification – Long-term integrity must be proven via pressure sensors and seismic surveys.

- Logistics Complexity – Design of CO₂ offloading arms and LCO₂ shipping requires new safety codes (ABS 2024 FIU guidelines).

Economics and Market Potential

- Capture Cost: US $60–90 per tonne CO₂ for offshore operations today.

- Revenue Pathways: Carbon credits, enhanced oil recovery (EOR), and storage fees.

- Payback: With carbon prices > $100 / t CO₂, F-CCS retrofits on existing FPSOs become economically viable.

- Synergies: Shared marine logistics with FLNG and CO₂ tankers reduce OPEX.

Financing is shifting rapidly. Equinor, Shell, and TotalEnergies are exploring green bonds tied to verified CO₂ storage volumes, while Asian shipyards are positioning to supply modular capture units under EPC-F contracts. Analysts expect total F-CCS market value to exceed US $8 billion by 2030 if even 10% of global offshore assets adopt capture technology.

F-CCS is thus positioned as a bridge between traditional offshore production and future net-zero operations.

Policy & Regulation

- Europe: The EU’s CCS Directive now covers offshore storage, enabling cross-border CO₂ transport (Northern Lights).

- USA: The Inflation Reduction Act (IRA) offers tax credits of $85–180 per tonne for verified storage, spurring Gulf of Mexico studies.

- Japan & Malaysia: National roadmaps include floating pilots under DeepCCS and Petronas-Technip collaboration.

- India: Draft National Carbon Capture & Storage Mission (2025) identifies depleted KG-Basin fields for pilot storage.

Supply-Chain and Equipment Opportunities

- Compression & Process Equipment: Compact multistage compressors, cryogenic pumps, and high-alloy piping.

- Subsea Hardware: Injection trees, safety valves, flow meters for CO₂ service.

- Digital Monitoring: Pressure & plume-tracking systems integrated with SCADA.

- Shipyards & Fabricators: Converting aging FPSOs or rigs into capture units.

Asia-Pacific and Indian Opportunities

Asia-Pacific is emerging as the most promising region for floating carbon capture:

- Malaysia: Petronas targets CO₂ management in all future offshore developments; Technip Energies is designing pilot modules.

- Japan & Korea: Government-backed DeepCCS and HyNet programmes plan floating CO₂ hubs for dense coastal areas.

- India: KG Basin and Mumbai High depleted fields offer storage potential. F-CCS could complement India’s upcoming National CCUS Policy.

- Singapore: Positioning itself as a CO₂ trans-shipment hub for the region.

For Indian service companies and equipment manufacturers, this represents a new frontier in offshore innovation — designing compression skids, cryogenic valves, and digital controls tailored for F-CCS vessels.

Future Outlook — Toward 2030 and Beyond

Analysts forecast that F-CCS will reach commercial maturity by 2030, paralleling FLNG’s evolution a decade earlier. With rising carbon prices and mandatory emissions caps, operators that invest early will gain:

- Regulatory Edge: Compliance with future offshore CO₂ rules.

- Brand Advantage: Low-carbon credentials for LNG and oil exports.

- Asset Flexibility: Repurposing of aging FPSOs instead of scrapping.

- Investor Appeal: Access to green financing and ESG funds.

Just as Prelude FLNG proved that mega-floaters can succeed offshore, F-CCS will prove that even emissions can be handled at sea.

Frequently Asked Questions (FAQ)

1. What is Floating Carbon Capture and how is it different from onshore CCS?

Floating Carbon Capture (F-CCS) is a marine system that captures CO₂ directly from offshore facilities instead of industrial plants on land. It is mobile and uses floating storage rather than fixed infrastructure.

2. Can existing FPSOs or FLNGs be retrofitted for F-CCS?

Yes. Retrofit modules can be installed on available deck space for CO₂ absorption and compression, using shared utilities and control systems.

3. How much CO₂ can a floating capture unit handle?

Pilot designs range from 0.5 to 2 million tonnes per year, depending on space and energy availability.

4. Where is the captured CO₂ stored?

In depleted offshore reservoirs or deep saline aquifers beneath the seabed; monitoring ensures long-term containment.

5. Is F-CCS commercially viable today?

Costs remain high, but with carbon prices above $100/t and government incentives, the first full-scale projects are expected before 2030.

Key Takeaways

- Floating Carbon Capture (F-CCS) extends the legacy of FLNG into the era of decarbonisation.

- It captures and stores CO₂ offshore — using existing infrastructure and new floating modules.

- Global pilots in Norway, Malaysia, and Japan signal rapid progress.

- Asia-Pacific and India offer major growth opportunities for manufacturers and service companies.

- Early adoption can turn offshore facilities into carbon-neutral production hubs by 2030.

Conclusion

Floating Carbon Capture (F-CCS) is the natural evolution of offshore engineering — shifting from energy production to emission management. By repurposing the lessons of FLNG and FPSO technology, it offers a realistic path toward net-zero offshore operations.

As FLNG proved the commercial feasibility of floating production, F-CCS will prove that offshore carbon management is 100% achievable.