The Hoisting System in a drilling rig is like the muscle of the operation. It lifts, lowers, and suspends heavy loads such as the drill pipe, casing, and other equipment. Without a strong and reliable hoisting system, no rig could drill deep into the earth.

In this article, we’ll break down the components, working, calculations, and safety aspects of the hoisting system—along with real-world examples to make it simple to understand.

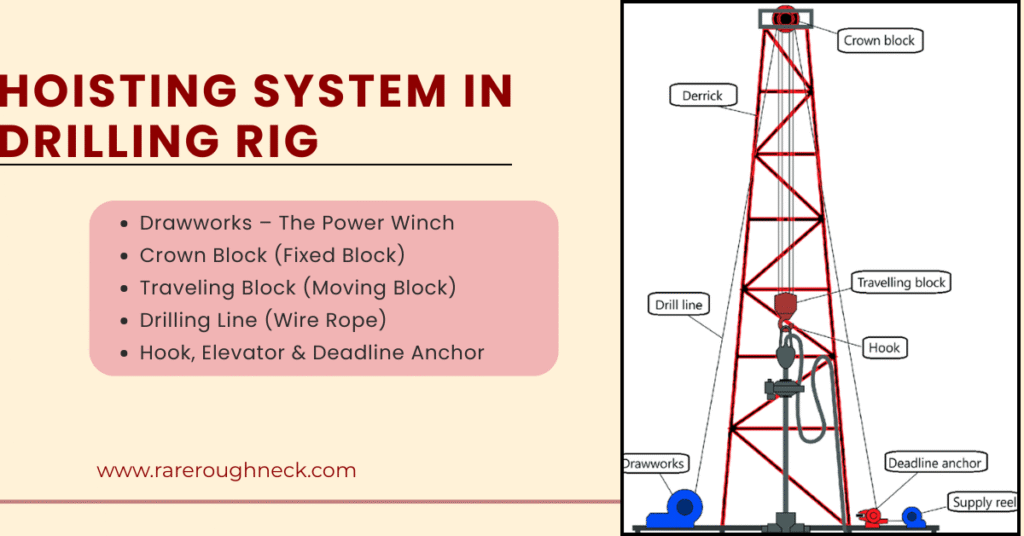

Main Components of the Hoisting System

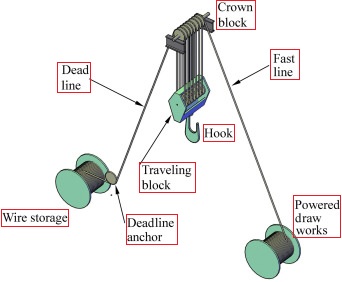

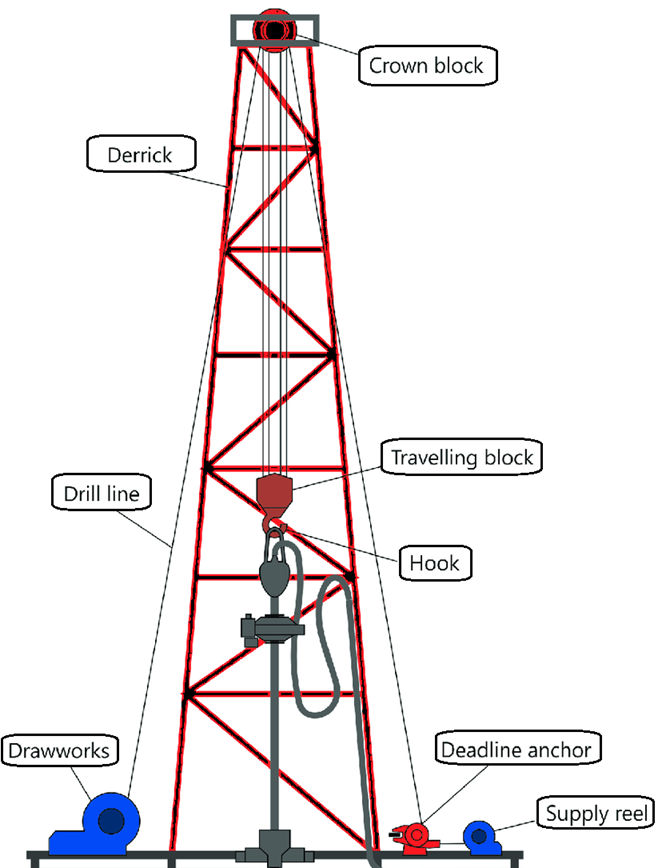

The Hoisting System in Drilling Rig is built around a block-and-tackle arrangement combined with a powerful drum winch. Let’s look at the key parts:

1. Drawworks – The Power Winch

- The drawworks is the main hoisting machine. It consists of a large drum, brakes, and drive system.

- It winds and unwinds the drilling line (wire rope) to lift or lower heavy equipment.

- Example: On land rigs, drawworks are powered by diesel engines with electric drives, while offshore rigs often use AC/VFD (variable frequency drive) systems for precision.

2. Crown Block (Fixed Block)

- Located at the very top of the derrick/mast.

- It has multiple sheaves (pulleys) over which the drilling line is reeved.

- Remains stationary but redirects the line toward the traveling block.

3. Traveling Block (Moving Block)

- Suspended by the drilling line from the crown block.

- Moves up and down when the line is wound/unwound from the drawworks drum.

- Together with the crown block, it creates mechanical advantage (lifting power).

4. Drilling Line (Wire Rope)

- High-strength steel rope wound several times between the crown and traveling blocks.

- The number of “line pairs” determines the lifting capacity.

- Example: A 10-line system distributes load so each segment carries only 1/10th of the hook load.

5. Hook, Elevator & Deadline Anchor

- Hook: Swivel-mounted hook that carries the drill string.

- Elevators: Clamps that hold drill pipe/casing.

- Deadline anchor: Secures one end of the wire rope; connected to a load sensor to measure hook load.

How the Hoisting System Works

Imagine you are lifting a 200-ton drill string:

- The drawworks drum winds the line.

- The traveling block rises, carrying the hook and elevators.

- Because the line passes through multiple sheaves (like a block-and-tackle crane), the load is divided.

- Example: In a 10-line reeving, each line carries only ~20 tons, reducing stress on the rope.

- Brakes on the drawworks control lowering speed and prevent runaway loads.

This setup allows the rig to safely lift hundreds of tons.

Example – Mechanical Advantage

- Drill string weight: 300,000 lbs (150 tons)

- Reeving: 12 line pairs

- Effective load per line = 300,000 ÷ 12 = 25,000 lbs per line

This mechanical advantage means the hoisting system can lift massive loads that would otherwise be impossible with a single rope.

Real-Life Example: Offshore Rig Operation

On a semi-submersible rig in the Gulf of Mexico:

- A drawworks rated at 3,000 HP with 14-line reeving is used.

- The system hoists a drill string over 5 miles long.

- The hook load can reach 750 tons, yet the system manages it smoothly thanks to line distribution and powerful braking.

Safety & Maintenance

The Hoisting System in Drilling Rig handles extreme loads, so safety is critical:

- Wire rope inspection: Look for broken strands, corrosion, or flattening.

- Brake checks: Drawworks brakes must hold maximum hook load.

- Lubrication: Crown and traveling block sheaves need proper grease.

- Load indicators: Ensure hook load sensors are calibrated.

Neglect can lead to accidents like line snaps or uncontrolled drops.

Pingback: Rotating System in Drilling Rig – Rotary Table, Kelly, Top Drive & Swivel Explained