Before the age of automated top drives, drilling rigs relied on a mechanical marvel — the Rotary Table in Drilling Rig.

This heavy-duty turntable, located on the rig floor, is responsible for transmitting rotational power to the drill string, allowing the bit to cut through subsurface rock.

It works hand-in-hand with the Kelly, Master Bushing, and Swivel, forming the core of the Rotating System that makes drilling possible.

Even today, thousands of onshore rigs across Asia, the Middle East, and Africa still use rotary tables due to their simplicity, low maintenance cost, and reliability.

📌 If the Hoisting System lifts the weight, the Rotary Table makes the hole.

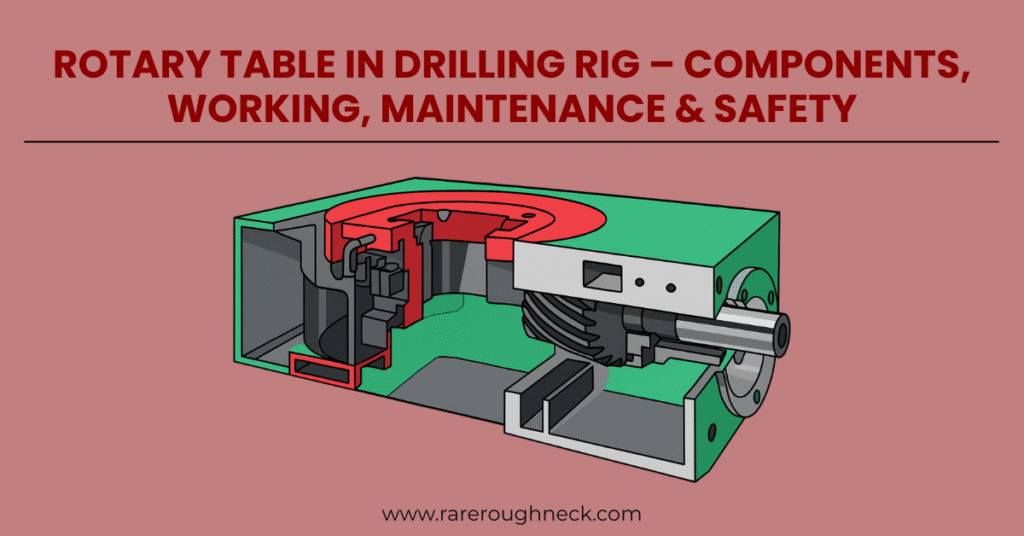

Construction and Components of Rotary Table

The Rotary Table in Drilling Rig is built to handle immense torque and axial loads. It sits flush with the rig floor and forms a stable base for the rotating system.

Key Components

| Component | Function |

| Rotary Table Base | Main structural housing, supports all internal gears and bearings. |

| Ring Gear & Pinions | Transfers power from drawworks or motor to rotate the table. |

| Main Bearing | Takes vertical loads from the drill string. |

| Hold-Down Bearing | Prevents upward lift when heavy torque is applied. |

| Mud Seal (Labyrinth Seal) | Prevents drilling mud and debris from entering bearing housings. |

| Master Bushing | Sits inside the table, supports kelly bushing and rotary slips. |

| Kelly Bushing | Connects to the kelly to transmit torque to the drill pipe. |

| Rotary Lock | Locks the table during connection or tripping operations. |

In chain-driven models, power is supplied from the drawworks or separate rotary drive motor through roller chains and sprockets.

Modern versions use electric or hydraulic drives, reducing mechanical loss and improving RPM control.

Working Principle – How the Rotary Table Rotates the Drill String

- Power Input: The table receives torque from the rig’s power system through chains, gears, or a direct motor connection.

- Rotation Transmission: The ring gear turns the master bushing and kelly bushing, which grip the kelly (square or hexagonal pipe).

- Torque to Drill String: As the kelly rotates, torque passes through the drill pipe down to the drill bit, cutting the rock.

- Support & Slips: When adding or removing pipe sections, the table supports the drill string through rotary slips set in the master bushing bowl.

- Locking Mechanism: The rotary lock secures the table when rotation must stop — preventing pipe rotation during makeup or breakout operations.

Typical rotation speed: 40–200 RPM, depending on formation hardness and bit design.

Torque capacity: 20,000 to 60,000 ft-lb, with load ratings up to 600 tons, per API 7K specifications.

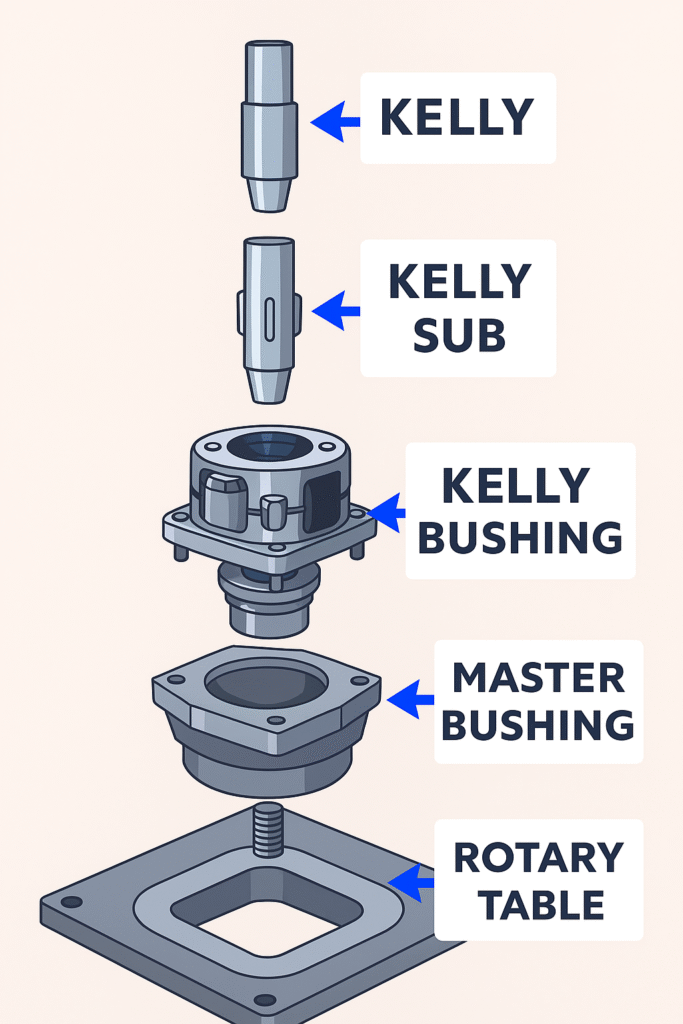

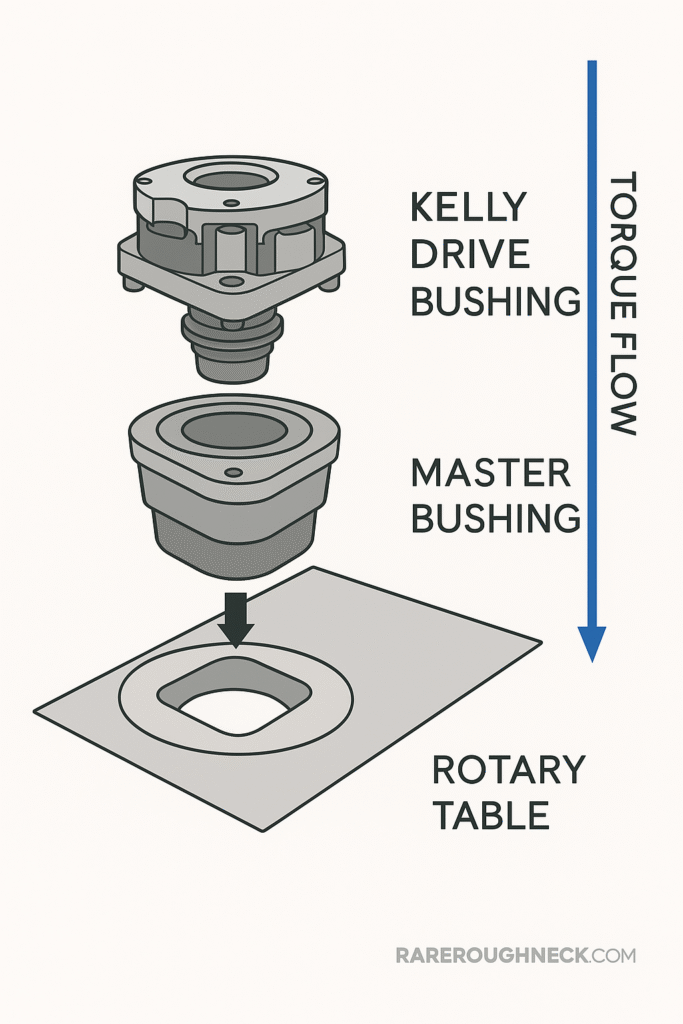

Master Bushing and Kelly Bushing – The Driving Interface

These two parts are crucial links between the rotary table and the drill string.

Master Bushing

- Fits into the rotary table and supports rotary slips or the kelly bushing.

- Tapered internal bowl allows slips to grip the drill pipe securely.

- Common types: solid, split, and hinged.

- Load ratings: 100 to 600 tons (API 7K).

Kelly Bushing

- Locks into the master bushing with drive pins or square slots.

- Transmits torque from the rotating table to the kelly.

- Two drive types:

- Square Drive (older rigs) – simpler, used on shallow wells.

- Pin Drive (modern) – provides smoother torque transfer.

💡 Analogy: Think of the master bushing as the gearbox casing and the kelly bushing as the output shaft transmitting power.

Rotary Slips – Holding the Drill String Securely

Rotary slips are wedge-shaped steel segments that fit into the master bushing bowl to grip the drill pipe when the string is suspended.

- Each slip has dies or inserts that bite into the pipe surface.

- The tapered outer surface matches the bowl’s taper to evenly distribute the load.

- Slips must be inspected for wear and replaced regularly to prevent pipe damage.

Common Slip-Related Hazards

- Deformation of slip bodies from uneven load.

- Pipe crushing due to improper die seating.

- Dropped string if slips are set in a dirty or damaged bowl.

Safety Tip: Never stop the drill string with slips — always slow the rotation first and ensure mud pressure is balanced.

Lubrication System of Rotary Table

Proper lubrication ensures long bearing life and smooth torque transmission.

Key Lubrication Points

- Main Bearing Housing – filled with oil bath or grease reservoir.

- Ring Gear Teeth – coated with heavy-duty open gear lubricant.

- Hold-Down Bearing – greased through central fitting weekly.

- Mud Seal & Labyrinth Seal – checked for contamination and cleaned daily.

Recommended Maintenance Schedule

| Frequency | Maintenance Task |

| Daily | Check oil level, clean mud seal, inspect chain tension. |

| Weekly | Grease main & hold-down bearings, inspect drive pins and gears. |

| Monthly | Change bearing oil, check alignment, test rotary lock. |

| Quarterly | Perform slip-test procedure, inspect bushing wear and replace if needed. |

Maintenance, Inspection & Troubleshooting

Common Issues and Fixes

| Problem | Likely Cause | Solution |

| Oil leakage from housing | Worn mud seal or loose bolts | Replace seal, torque bolts to spec |

| Overheating bearing | Insufficient lubrication | Refill oil bath, inspect circulation |

| Unusual vibration | Worn pinion or misaligned gear | Realign gears, replace worn teeth |

| Noisy operation | Chain too tight or dry | Adjust chain tension, apply grease |

| Difficulty in locking table | Damaged rotary lock pin | Replace locking mechanism |

Slip-Test Procedure (API Recommended)

- Clean slip bowl and dies.

- Apply measured hook load incrementally.

- Wrap pipe with test paper to check die marks.

- Record load at which slip begins to slide.

- Compare against rated load; replace if below 80%.

Rotary Table Safety Precautions

- Always lock the rotary table before connecting or breaking out pipes.

- Never stand on the table while it’s rotating.

- Use safety clamps when handling drill collars or heavy tubulars.

- Keep mud and debris clear of master bushing bowl.

- Inspect chains, pins, and bearings during every shift change.

- During maintenance, use lock-out tags on the power line.

A well-lubricated, properly maintained rotary table is not just efficient — it’s safe for everyone on the drill floor.

From Rotary Table to Top Drive – The Modern Transition

While the rotary table system remains reliable for vertical and shallow wells, most modern rigs have shifted toward Top Drive Systems.

Key Differences:

| Feature | Rotary Table | Top Drive |

| Torque Transmission | Indirect (via kelly drive) | Direct motor drive |

| Connection Speed | 2–3 minutes | 1 minute |

| Safety | Manual pipe handling | Automated control |

| Directional Drilling | Limited | Excellent |

| Cost | Low | High (but efficient) |

Yet, in rugged onshore regions like Rajasthan, Oman, and Egypt, rotary tables still dominate because they’re mechanically simpler, easier to repair, and less power-dependent.

API Rotary Table Sizes and Load Capacities (Reference)

| API Size | Opening (in) | Load Rating (tons) | Typical Use |

| 17½ | 17.5 | 100–150 | Shallow wells, water wells |

| 20½ | 20.5 | 200–250 | Light oil rigs |

| 27½ | 27.5 | 300–350 | Medium drilling rigs |

| 37½ | 37.5 | 500 | Heavy land rigs |

| 49½ | 49.5 | 600+ | Offshore or ultra-deep rigs |

Source: API Spec 7K

FAQ – Quick Answers

Q1: What is the function of a rotary table?

It rotates the drill string and supports its weight while transmitting torque from the rig’s power system to the drill bit.

Q2: What is the difference between a master bushing and a kelly bushing?

The master bushing sits in the rotary table and supports slips or the kelly bushing, while the kelly bushing engages the kelly to transmit torque.

Q3: How often should a rotary table be lubricated?

Main bearings and gears should be lubricated weekly, seals cleaned daily, and oil changed monthly — depending on drilling conditions.

Q4: Why are top drives replacing rotary tables?

Top drives offer faster connections, improved safety, and better control for directional drilling — though rotary tables remain economical for simpler wells.

The Rotary Table remains one of the most iconic and dependable pieces of equipment in drilling history.

While automation and top drives have changed the game, the rotary table continues to power rigs where simplicity, durability, and field serviceability matter most.

From the master bushing to the labyrinth seal, every part plays a vital role in keeping the rotation steady and the drilling safe.